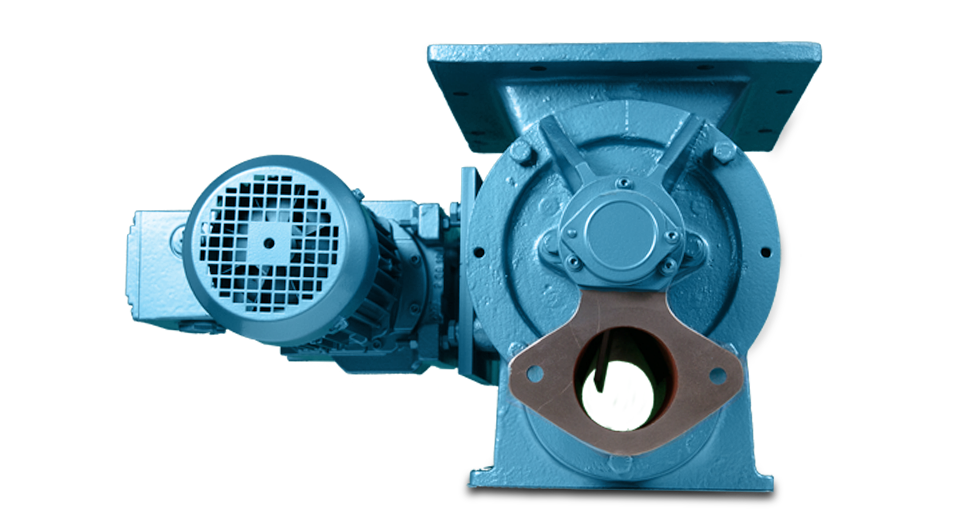

Blo-thru Rotary Airlocks meet the specific needs of the pneumatic conveying industry, a natural extension to the Rotary Airlock; both products are used to regulate the flow of dry powder, dust or granular product, while maintaining an airlock.

The Blo-thru Rotary Airlock has distinct advantages for the specialist as it introduces high pressure conveying air through the airlock body and rotor pocket ensuring – HIGH EFFICIENCY THROUGHPUT WITH LOW EFFECTIVE PRESSURE DROP.

This is achieved by the fact that more blades are in contact for longer periods with the valve body resulting in less air leakage – and by blowing through the rotor each rotor pocket is efficiently emptied.

The Rotolok range of blo-thru airlocks is robustly constructed with an emphasis on close tolerances and minimal eccentricities, making the unit suitable for the majority of pneumatic conveying applications and is available is sizes ranging from 5″ up to 18″.

-

Body

Cast Iron or Stainless Steel precision machined

-

End Covers

Cast Iron or Stainless Steel spigot located in body

-

Rotor

Fabricated Mild or Stainless Steel fixed bladed open type

-

Bearings

Ball type sealed for life – alternative high temperature to 750°F

-

Seal

PTFE packing gland

-

Drive

NEMA Frame C-Face TEFC motor mounted to parallel shaft gear reducer sidewall mounted to airlock body complete with taper lock chain drive in an enclosed guard.

All dimensions are in inches unless otherwise stated

*Side holes ø1/2”, end holes tapped M10

| SIZE | A | A1 | B | B1 | C | D | E | F | G | H | J | K | L | M | N | P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5’’ | 5’’ | 5’’ | 8’’ | 8 ⅛’’ | ½’’ | 4 ⅜’’ | 9 ½’’ | 11 ½’’ | 6 ¼’’ | 9 ½’’ | 12 ⅝’’ | 8 ⅝’’ | 7 ⅛’’ | 28mm | 3 ¾’ | 8 |

| 8’’ | 8’’ | 8’’ | 11 ¹³⁄₁₆’’ | 11 ¹³⁄₁₆’’ | ½’’ | 6 ¼’’ | 13 ⅜’’ | 11’’ | 7 ⅞’’ | 11 ⅛’’ | 13 ¾’’ | 10 ¼’’ | 8 ⅝’’ | 28mm | 5’’ | 8 |

| 9’’ | 7’’ | 7 ⅞’’ | 11 ¹³⁄₁₆’’ | 11’’ | ⅝’’ | 7 ⅛’’ | 13 ⅜’’ | 12’’ | 8 ⅞’’ | 12 ⅞’’ | 17 ⅛’’ | 11 ¼’’ | 9 ⅝’’ | 40mm | 6 ½’’ | 8 |

| 11’’ | 8 ⅞’’ | 10 ⅝’’ | 13 ⅝’’ | 14 ⁹⁄₁₆’’ | ⅝’’ | 8 ⅛’’ | 17 ⅛’’ | 11 ⅝’’ | 10 ³⁄₁₆’’ | 14 ¼’’ | 18 ⅛’’ | 12 ⅝’’ | 11’’ | 40mm | 7 ½’’ | 8 |

| 14’’ | 10’’ | 13 ¾’’ | 13 ¾’’ | 17 ¾’’ | ⁹⁄₁₆’’ | 9 ½’’ | 18 ⅜’’ | 9’’ | 12 ⅜’’ | 16 ¾’’ | 22 ⅜’’ | 15 ¼’’ | 13 ⅛’’ | 50mm | 9’’ | 10 |

| 18’’ | 12 ¼’’ | 15 ¾’’ | 16 ⅛’’ | 20 ⅛’’ | ⁹⁄₁₆’’ | 11 ⅜’’ | 19 ⅝’’ | 7 ½’’ | 13 ¾’’ | 18 ⅛’’ | 24 ⅝’’ | 16 ⅝’’ | 14 ½’’ | 50mm | 10 ⅝’ | 10 |

All dimensions are in inches unless otherwise stated

*Side holes ø1/2”, end holes tapped M10

| SIZE | Q | R | S | T | W | X | Y | Z | AA | AB | AC | AD | AE | AF | AG | HP |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5" | ⅜’’ | 8mm | 7mm | 3 ⅛’’ | 3 ⁹⁄₁₆’’ | 6 ¹¹⁄₁₆’’ | 3 ⁹⁄₁₆’’ | 6 ¹¹⁄₁₆’’ | 3 ⁹⁄₁₆’’ | 5’’ | 3 ¾’’ | 2’’ | ⁷⁄₁₆’’ | ¾'' | 3 ¹⁄₁₆'' | ½ |

| 8" | ½’’ | 8mm | 7mm | 4’’ | 5 ⅛’’ | 10 ⅝’’ | 5 ⅛’’ | 10 ⅝’’ | 5 ⅛’’ | 7 ½’’ | 5 ⅛’ | 3’’ | ⁷⁄₁₆’’ | ¾'' | 4 ⁵⁄₁₆'' | ½ |

| 9" | * | 12mm | 8mm | 4 ⅜’’ | 5 ⅛’’ | 9 ⅞’’ | 3 ¹⁵⁄₁₆’’ | 9 ⅞’’ | 5 ⅛’’ | 8 ⅞’’ | 4 ⁵⁄₁₆’’ | 2 ⁹⁄₁₆’’ | ⁹⁄₁₆’’ | ¾'' | 3 ¹⁵⁄₁₆'' | 1 |

| 11" | ½’’ | 12mm | 8mm | 6 ¼’’ | 7 ¹⁄₁₆’’ | 13 ³⁄₁₆’’ | 7 ¹⁄₁₆’’ | 12 ¹⁄₁₆’’ | 7 ¹⁄₁₆’’ | 12 ⅛’’ | 6 ¹¹⁄₁₆’’ | 3 ⅞’ | ⁹⁄₁₆’’ | ¾'' | 5 ⅛'' | 1 |

| 14" | ⁹⁄₁₆’’ | 14mm | 9mm | 7 ⅞’’ | 11 ¹³⁄₁₆’’ | 16 ⁹⁄₁₆’’ | 7 ¹⁄₁₆’’ | 12 ⅝’’ | 12 ⅝’’ | 2@5 ²⁹⁄₃₂’’ | 7 ⅛’’ | 4 ⁵⁄₁₆’’ | ⁹⁄₁₆’’ | ⅞'' | 5 ¹¹⁄₁₆'' | 1 ½ |

| 18" | ⁹⁄₁₆’’ | 14mm | 9mm | 9’’ | 12 ⅝’’ | 18 ⅞’’ | 8 ¹¹⁄₁₆’’ | 14 ¹⁵⁄₁₆’’ | 15’’ | 2@5 ⁵⁄₁₆’’ | 7 ⅞’’ | 4 ¹⁵⁄₁₆’’ | ⁹⁄₁₆’’ | ⅞'' | 6 ¹⁄₁₆'' | 1 ½ |

Restricted Content

This page contains content that is available to registered users only.

To view the restricted content, please log in or create an account to gain access to view the resources.

Login

Register for account

Register* Once your account has been approved , your password will be autogenerated and emailed to your registered e-mail address