The main feature of a Rotary Airlock is to regulate the flow of material from one chamber to another while maintaining a good airlock condition. The material or product being handled is usually dry free flowing powder, dust or granules.

The granule type of product, especially if it is a plastic type, polythene or nylon etc., does not shear easily and consequently, without considerable care the standard drop-through type of valve leads to valve seizure and also considerable shock loadings.

To minimize these problems the Offset Rotary Airlock ensures lower pocket fillage as its design means that the rotor is still being filled in the upward cycle with the pellets falling away at the shear point. Similarly, the pelican beak distributes the product across the full width of the rotor.

Offset Rotary Airlocks are offered in sizes ranging from 8″ up to 20″.

-

Bodies

Cast Iron, Stainless Steel or Aluminum precision bored.

-

End Covers

Cast Iron, Stainless Steel or Aluminum spigot located inbody for concentricity.

-

Rotor

Fabricated Mild or Stainless Steel.

-

Bearings

Generally sealed-for-life-ball type rigged outboard or high temperature above 480ºF

-

Shaft Seal

Gland type with PTFE packing.

-

Drive

TEFC C-Face motor mounted to parallel shaft Gearbox and complete with taper lock sprockets chain drive all in an enclosed guard

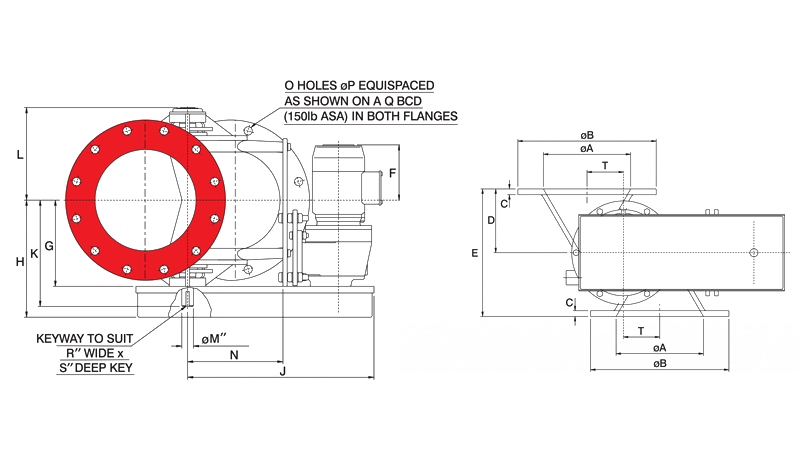

All dimensions are in inches unless otherwise stated

| SIZE | A | A1 | B | B1 | C | D | E | F | G | H | J | K |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8’’ | 7 ⅞’’ | 6’’ | 12’’ | 10’’ | ½’ | 6 ½’’ | 13’’ | 14 ⅝’’ | 7 ⅞’’ | 11 ⅛’’ | 17 ¼’’ | 10 ¼’’ |

| 10’’ | 10’’ | 7’’ | 14’’ | 11’’ | ⅝’’ | 8’’ | 16’’ | 11 ⅞’’ | 9’’ | 12 ¼’’ | 18 ⅞’’ | 11 ⁷⁄₁₆’’ |

| 12’’ | 12’’ | 8’’ | 16’’ | 12’’ | ¾’’ | 9’’ | 18’’ | 11 ⅝’’ | 10 ¼’’ | 14 ¼’ | 20 ⅛’’ | 12 ⅝’’ |

| 16’’ | 16’’ | 10’’ | 22’’ | 16’’ | ⅞’’ | 11’’ | 22’’ | 7 ¾’’ | 13 ⅛’’ | 17 ⅛’’ | 24 ⅝’’ | 15 ⅞’’ |

| 18’’ | 18’’ | 11’’ | 24’’ | 17’’ | ⅞’’ | 12 ⅞’’ | 25 ¾’’ | 8 ⅞’’ | 14’’ | 18’’ | 26 ¼’’ | 16 ½’’ |

| 20’’ | 20’’ | 12’’ | 26’’ | 18’’ | 1’’ | 14 ³⁄₁₆’’ | 28 ⅜’’ | 7 ⅞’’ | 15’’ | 19’’ | 26 ¼’’ | 17 ⅞’’ |

All dimensions are in inches unless otherwise stated

| SIZE | L | M | N | O | P | R | S | T | V | W | X | Y | HP |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8’’ | 8 ⅝’’ | 28mm | 5 ¼’’ | 8 | ⁹⁄₁₆’’ | 8mm | 7mm | 1 ⅝’’ | 10 ¾’’ | 7’’ | 8 ¾’’ | 5’’ | 1 |

| 10’’ | 9 ¾’’ | 35mm | 6 ⅛’’ | 8 | ⁹⁄₁₆’’ | 10mm | 8mm | 1 ⅞’’ | 12 ¾’’ | 6’’ | 9 ¾’’ | 6’’ | 1 |

| 12’’ | 11’’ | 35mm | 7 ¼’’ | 8 | ⁹⁄₁₆’’ | 10mm | 8mm | 2 ⅜’’ | 14 ¾’’ | 7 ¼’’ | 10 ¾’’ | 6 ½’’ | 1 ½ |

| 16’’ | 13 ⅞’’ | 50mm | 9 ¼’’ | 14 | ¾’’ | 14mm | 9mm | 3 ⅜’’ | 20 ¼’’ | 10 ½’’ | 14 ¼’’ | 6’’ | 1 1½ |

| 18’’ | 14 ⅞’’ | 50mm | 10 ¼’’ | 14 | ¾’’ | 14mm | 9mm | 3 ⅜’’ | 22 ¼’’ | 11’’ | 15 ¼’’ | 6’’ | 2 |

| 20’’ | 15 ¾’’ | 50mm | 11 ¼’’ | 14 | ¾’’ | 14mm | 9mm | 3 ⅞’’ | 24 ¼’’ | 12’’ | 16 ¼’’ | 6’’ | 3 |

All dimensions are in inches unless otherwise stated

| SIZE | ØA | ØB | C | D | E | F | G | H | J | K |

|---|---|---|---|---|---|---|---|---|---|---|

| 8’’ | 8’’ | 13 ½’’ | ⅝’’ | 6 ½’’ | 13’’ | 13’’ | 7 ⅞’’ | 11 ⅞’’ | 20 ⅜’’ | 10 ¼’’ |

| 10’’ | 10’’ | 16’’ | ¾’’ | 7 ½’’ | 15’’ | 12 ⅞’’ | 9’’ | 12 ¼’’ | 22 ¼’’ | 11 ⅜’’ |

| 12’’ | 12’’ | 19’’ | ¾’’ | 8 ¾’’ | 17 ½’’ | 10 ⅝’’ | 10 ¼’’ | 14 ¼’’ | 24 ⅝’’ | 12 ⅝’’ |

| 14’’ | 14’’ | 21’’ | ⅞’’ | 10 ½’’ | 21’’ | 10 ¼’’ | 10 ⅝’’ | 14 ⅝’’ | 25 ⅝’’ | 13’’ |

| 20’’ | 20’’ | 27 ½’’ | 1’’ | 14’’ | 28’’ | 8 ⅞’’ | 15’’ | 19’’ | 30 ⁹⁄₁₆’’ | 17 ⅞’’ |

All dimensions are in inches unless otherwise stated

| SIZE | L | ØM | N | O | ØP | ØQ | R | S | T | HP |

|---|---|---|---|---|---|---|---|---|---|---|

| 8’’ | 8 ⅝’’ | 28mm | 7 ⅞’’ | 8 | ⅞’’ | 11 ¾’’ | 8mm | 7mm | 3 ⅜’’ | 1 |

| 10’’ | 9 ¾’’ | 35mm | 9 ¾’’ | 12 | 1’’ | 14 ¼’’ | 10mm | 8mm | 4 ¼’’ | 1 |

| 12’’ | 11’’ | 35mm | 11 ⁵⁄₁₆’’ | 12 | 1’’ | 17’’ | 10mm | 8mm | 5’’ | 1 ½ |

| 14’’ | 11 ⅜’’ | 35mm | 13’’ | 12 | 1 ⅛’’ | 18 ¾’’ | 10mm | 8mm | 5 ½’’ | 1 |

| 20’’ | 15 ⅞’’ | 50mm | 15 ½’’ | 20 | 1 ¼’’ | 25’’ | 14mm | 9mm | 7 ⅞’’ | 3 |