Rotolok’s range of Rotary Airlocks are found in many demanding applications and one of the latest is in the development & production of lithium-ion batteries for use in electric vehicles.

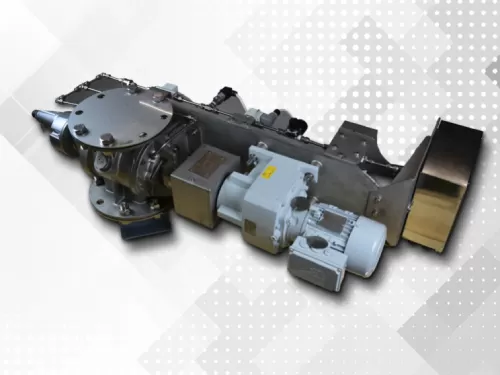

We have recently completed the supply of 15 stainless steel rotary airlocks that had highly defined specifications and a stringent documentation requirement.

Working for a major battery manufacturing company, the Rotolok team developed a close working relationship with the customer and were able to meet the strict selection criteria for the project. Each rotary airlock was fitted with a range of ancillary components to control purging to both the sealing glands and the body cavity. Each component had to be individually specified and tagged with custom data sheets provided and approved by the customer, including the electrical control wiring.

This meant document control was a key function of the project. Our quality and design teams put in an exceptional effort to ensure documentation was provided on time and to standard, which was recognized in the final report from the client.

The assembly of each airlock had to be strictly monitored to ensure it met the design and application criteria and were ready for the factory acceptance test, witnessed by the customer. Every member of the design and assembly team rose to the task with our product designer stepping out from behind his desktop and putting hours in on the shop floor to assist the assembly team with his design knowledge proving invaluable.

The customer was extremely complimentary of the overall project delivery, and it is a prime example of the values promoted within the company.

Back to News