Here at Rotolok, we constantly strive to improve the quality of our equipment and obtain the required and industry recognised certification to provide specialist valves. In February 2018, Rotolok gained approval and certification from the United States Department of Agriculture (USDA) to supply Rotary Valves for use in the dairy, food and chemical industries in the United States.

Rotolok’s USDA Dairy Accepted line of Rotary Valves are designed for use in sanitary applications in the food, dairy, pharmaceutical and chemical industries where regular cleaning is required to prevent product contamination.

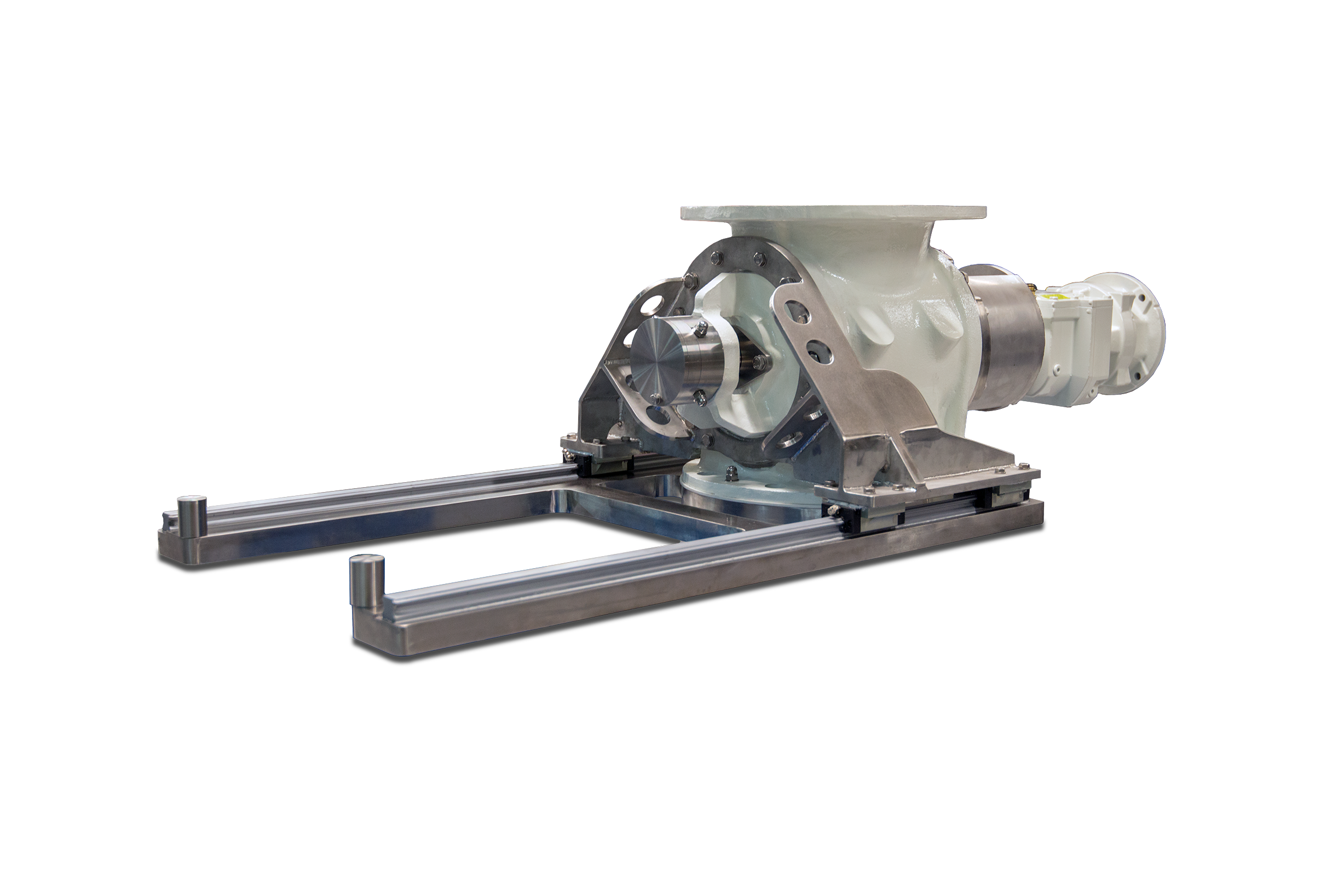

The product contact surfaces of the valve are manufactured in 316 Stainless Steel and polished to a 150 grit finish, ensuring that there are no lodgement points allowing the product to flow smoothly. Furthermore, the valve is equipped with a slide rail mechanism allowing for the quick and easy removal of the rotor from the valve body. This addition substantially reduces the amount of downtime and the number of man hours required for the cleaning and maintenance of the rotor and valve internals.

Our USDA certified Rotary Valves are available in sizes ranging from 150mm up to 400mm.

-

Bodies

316 Stainless Steel

-

End Covers

316 Stainless Steel

-

Rotor

Fabricated Stainless Steel with Scalloped pockets

-

Bearings

Sealed-for-life ball type rigged outboard

-

Shaft Seal

Cartridge style shaft seal

-

Drive

Direct drive coupled

Sizes range up to 600mm

- Quick Release

- Easy Release

- Bevelled Vanes

- Air Purge

- Atex

- Chrom Plating