The Rotolok Rotospeed Switch can be used whenever and wherever shaft monitoring is required. Its compact design and trouble free operation makes it ideal for Rotary Airlock, Screw Conveyor and Bucket Elevator applications, for overspeed and underspeed detection.

The Rotospeed Switch was developed initially to economically monitor Rotolok’s Rotary Valves around the clock, replacing labour intensive visual supervision.

Other applications (e.g. belt conveyors, elevators and vee drives) however require more sophisticated overspeed and underspeed detection, so the Rotospeed has been upgraded to meet these needs.

-

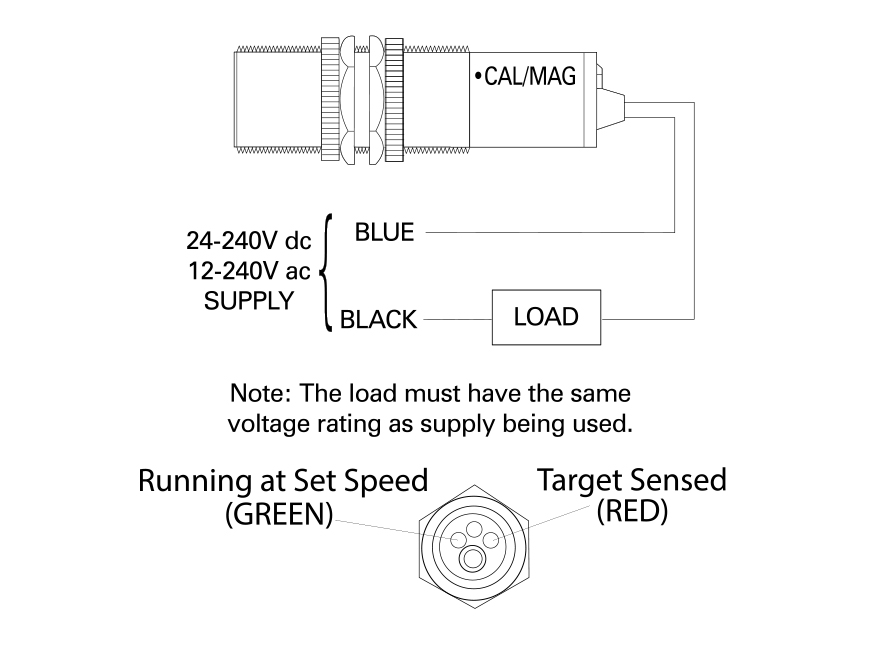

Supply

12-240V DC

24-240V AC

-

Fusing

Supply to be fused at 5A max

-

Switching Capacity

200mA max

-

Saturation Voltage

6 volts max (output on)

-

Ambient Temp

-15oC to + 50oC

-

Output State

Normally closed (Volt drop 6 volts max) above set speed. Normally open (leakage current 1.6mA max)

-

Trip Level

20% below set speed

-

Relative Humidity

90% RH

-

Start Up Delay

Adjustable to 0 – 60 seconds

The heart of the switch is its sensing head with its built in switching device. The head detects the blades of a rotor mounted on the shaft to be monitored. The sensing head switch is activated when the rotor frequency matches or exceeds the switch’s setting frequency.

The switch will de-activate when the rotor frequency falls below the switch’s setting frequency.

The switch is suitable for operation over a range of 2.5 to 200 RPM but this range can be extended if details are given on application.

Care must be taken not to overload the switch and these details are as charted. In all cases it is recommended to install’ prior to the Rotospeed, a 5A protection fuse.

(Different sensing heads can be used for alternative applications,

(Details given on application))

The shaft being monitored should be tapped M12 in accordance with the planning in drawing and to overcome the problem of eccentricity or the hole not being coaxial, an anchor bracket should be fitted to stop rotation of the switch. By locating rather than bolting the Rotospeed firmly to the bracket, bearing overload is prevented.

All dimensions are in mm unless otherwise stated

The total unit is housed in a weatherproof cast aluminium housing and can be directly coupled to the monitored shaft and is suitable for running in clockwise or anticlockwise direction.

The proximity switch provides an open circuit when de-energised and operates from a 12-240V DC or 24-240V AC 50/60 Hz supply. Mounting positions can be horizontal, vertical or at any convenient angle.