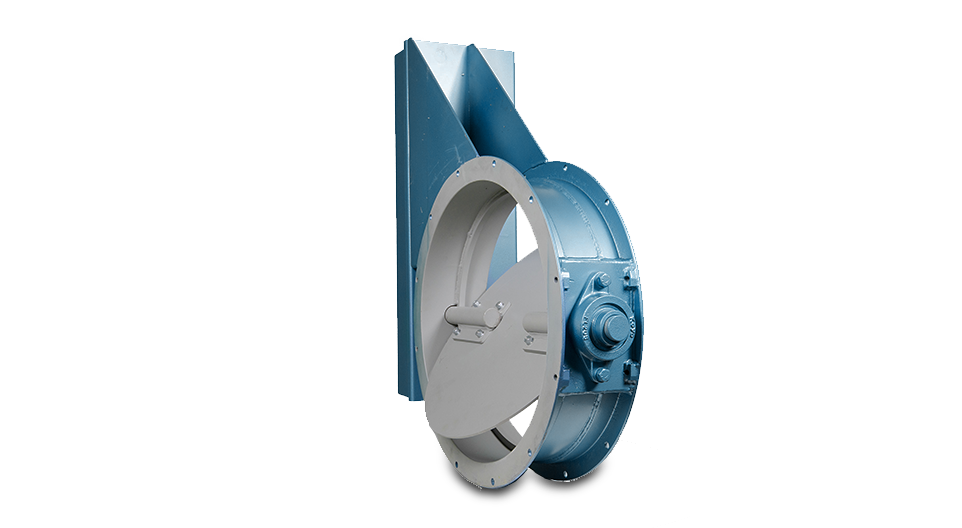

The fabricated range of Rotolok Butterfly Dampers are used extensively in the air and dust handling industries generally in fan systems.

They are normally operated remotely by air cylinders, electric or pneumatic actuators, although manual versions through the customary hand lever, handwheel and reduction gearboxes can be accommodated.

Manufactured in sizes ranging from 16″ to 28″.

Construction is generally from Mild or Stainless Steel with the body of the valve formed from rolled steel angles or channels dependent on the size. The Damper itself is formed from two plates which sandwich, if required, a felt seal or alternatively it can be a single blade sized for close fitment to the valve body. The type selected is dependent on the amount of air leakage that can be accepted.

The split spindle mounting system minimizes turbulence within the air stream and these spindles are mounted on either two or four bolt flange mounted sealed for life bearings. Seals can be fitted if required through a simple ‘O’ ring or, on high temperature applications, the conventional stuffing box is utilised.

The type of actuator, to suit the clients requirements or specification, can be added to all sizes and, on pneumatic versions, limit switches and single solenoid spring return valves are included.

With fabrication, practically any size can be accommodated to suit the duct size with flanges also made to suit system designers needs.

The range starts at 14’’ diameter and extends to 59’’ in diameter. Standard sizes are as shown in the chart below. Square units and special sizes can, and have, been supplied. On valve size selection it is important to ensure that the ducting size is equal to or slightly larger than the valve.

This is to prevent any possible interference during the damper operation in the area where the blade enters the ducting, or should there be any misalignment between the components on assembly.

All dimensions are in inches unless otherwise stated

| SIZE | A | B | C | D | E | F | G | H | K | L |

|---|---|---|---|---|---|---|---|---|---|---|

| 16’’ | 16’’ | 19 ½’’ | 5 ⅛’’ | 8’’ | 14 ⅝’’ | 23 ¼’’ | 12 | ⅜’’ | 18 ¼’’ | ¼’’ |

| 18’’ | 18’’ | 21 ½’’ | 5 ⅛’’ | 8’’ | 15 ⅝’’ | 23 ¼’’ | 12 | ⅜’’ | 20 ¼’’ | ¼’’ |

| 20’’ | 20’’ | 24 ⁵⁄₁₆’’ | 5 ⅞’’ | 8’’ | 17 ⅛’’ | 23 ¼’’ | 12 | ½’’ | 22 ⅝’’ | ¼’’ |

| 24’’ | 24’’ | 28 ⅜’’ | 5 ⅞’’ | 8’’ | 19 ⅛’’ | 23 ¼’’ | 16 | ½’’ | 26 ⅝’’ | ¼’’ |

| 28’’ | 28’’ | 32 ⅜’’ | 5 ⅞’’ | 8’’ | 21 ⅛’’ | 23 ¼’’ | 16 | ½’’ | 30 ⅝’’ | ¼’’ |